ABOUTNEW DONGHO

Ultrasonic welding leading brand

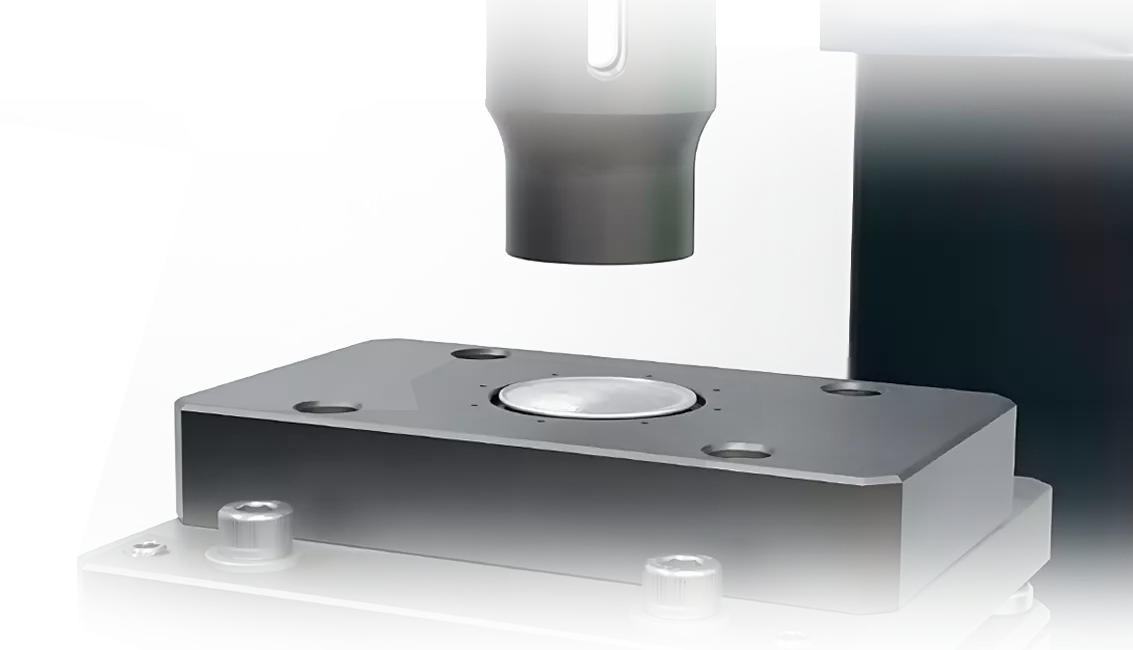

New Dongho ultrasonic machinery co., LTD., is a dedicated to technology innovation, focus on intelligent ultrasonic plastic welding and ultrasonic metal welding research and development and production providers, plastic welding industry and new energy automobile power battery welding system, non-contact welding system research and development, production and sales, and European and American technology to establish industry leadership, provide technical solutions, select the best products, specializing in service customers, improve the overall industry level. Introduce high-quality, sustainable, environmentally friendly raw material products for the local market. To provide for the global plastic and new energy application of one-stop solutions, to do the heart to protect the earth.

Advantage core. Create new areas of the industry

New Dongho in plastic welding, non-ferrous metal welding, system, supporting module industry chain key areas, has the core technology advantage and sustainable research and development team, formed a comprehensive and perfect production service system, the company in ultrasonic large data technology, independent research and development of Datalog and with hardware and software related using large-scale application in MES, leading enterprises in the field of DPS system. The product status can be effectively tracked. The server side can optimize the data collection and application of networked products to continuously upgrade and improve the product integrity.

NEW DONGHO pursuit of excellent quality. Meet customer needs

NEW DONGHO the company is at the forefront of the industry in research and development and product design.

Through ISO verification, and obtained 100 patents at home and abroad.

Adhering to the concept of one-stop service to create greater value for customers, we have reached a stable and long-term strategic cooperation relationship with the world first-class customers in the field of consumer electronics. Company this "customer oriented, full management" enterprise development, actively explore the international market, with perfect sales and service network, the company in Taoyuan, tazhong, Kuala Lumpur, Hanoi, Dongguan, kunshan, Weifang has sales service branches, let the customer experience zero distance, the first time to provide services and solutions.

ONE STOP SERVICE

Innovations

Enterprising

Experienced

Quality Assurance

Facing Future

HISTORY

2014

Taichung technology R&D center set up.

Taichung New Dongho Ultrasonic Machinery Co., Ltd. was established.

Weifang Dongho Ultrasonic office set up.

In terms of technology research and development, the company has a laboratory, the research and development personnel with years of unique experience and the latest knowledge, to assist customers to design and develop new products.

2015

Dongguan Dongho Ultrasonic Machinery Co., LTD was established.

Hanoi Dongho Ultrasonic Machinery Co., LTD was established.

Customer expansion pace, the active layout of the global production base, flexibly to meet the production needs of different customers in different regions, as well as to provide customers with the most convenient and fast service, and work together with customers to develop together.

2017

Kunshan Dongho Ultrasonic Machinery Co., LTD was established.

Weifang New Dongho Ultrasonic Machinery Co., LTD set up.

In order to meet the production needs of different customers in different regions, to create additional value, to provide the most convenient and fast service.

2018

Kuala Lumpur Dongho Ultrasonic office set up.

In order to continue to expand the global base and provide quality services for customers at home and abroad, the Kuala Lumpur Marketing Service Office was also established. The main business projects include ultrasonic plastic welding, ultrasonic metal welding, ultrasonic mold design and other projects.

2020

Taoyuan New Dongho Ultrasonic Machinery Co., Ltd. was established.

Through the brand-oriented business model to obtain successful cases, create added value, the global operation layout.